The project construction contractor also lauded the use of 3D technology on the project. Working with Bentley staff, the Hatch team expanded the library with custom objects reflecting the project design, according to Ondrej Krivka, Hatch’s lead modeler on the project. While OpenBridge includes a library of templates for common bridge components, such as abutments, piers, and barriers, the Lathams Road bridge called for unique shapes not included in the library. The bridge design team also developed custom objects in OpenBridge to accurately model bridge components. The post-tensioned concrete “stitch” was then placed from above, connecting the two spans, and all other bridge work was conducted from atop the structure.

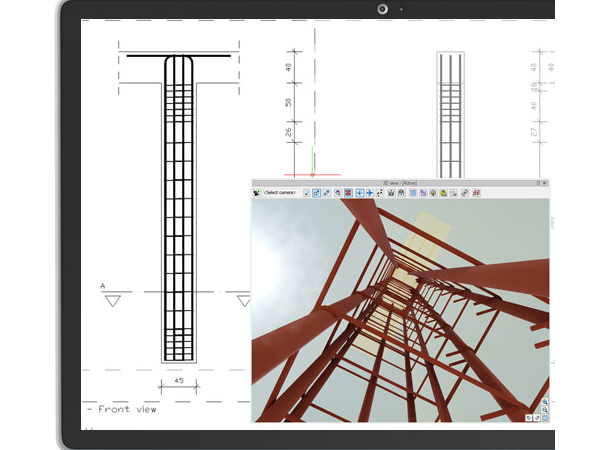

The freeway was only closed briefly to lift the beams into position, he noted. “The bridge was designed with a specific sequence,” said Vegad. With a set of five 36.5-meter-long, 1.5-meter-deep prestressed beams spanning each side of the freeway, the precast beams could be placed with minimal disruption to the roadway below. By tying the two spans together with post-tensioned, high-strength steel rods through the ends of each prestressed concrete beam, loads are distributed across both spans, enabling beam depth to be shallower than with simply supported spans, according to Vegad. To do this, the team developed a continuous beam design, which essentially ties two bridge spans together and enables beams to span longer distances. The railing design was integrated with the new bridge model, enabling the information to be used to determine quantities and order materials.įor the new bridge, the team faced another challenge: spanning the existing Mornington Peninsula Freeway without interrupting traffic. The team was able to model the railing system and replace the existing railings with a stronger design that met standards without requiring modifications to the existing bridge structure, noted Vegad. Due to updated Australian standards, the railings on the existing bridge did not meet current standards for collision resistance, requiring upgrades in conjunction with the new bridge. The 3D approach also helped the team design modifications to the existing bridge. While the team had experience with OpenRoads Designer, the project marked the first time Hatch had used OpenBridge Modeler. He estimates the changes would have taken four to five weeks using traditional methods. “If we did not have the 3D modeling approach, this wouldn't have been possible,” said Tanmay Vegad, senior bridge engineer for Hatch. The ability to seamlessly exchange information between bridge and road models greatly simplified the process, according to team participants. Using Bentley Systems’ OpenRoads Designer and OpenBridge Modeler to develop designs and 3D models, the team was able to adjust road and bridge geometry and make the necessary adjustments in a week, a fraction of the time required using traditional 2D methods. The Lathams Road project widened an existing road from two to four lanes and added a new bridge over an existing freeway. As an existing bridge abutment location differed from as-built records by approximately 300 millimeters, the team had to adjust road and bridge alignments accordingly after design was already in progress.

Concrete barrier lumenrt template software#

When Hatch Ltd., the project’s lead designer, discovered the existing bridge location did not match as-built survey information, the team turned to 3D design software to help make design adjustments.

Concrete barrier lumenrt template upgrade#

The AUD 150-million Lathams Road upgrade project includes widening a two-lane road to four lanes over a length of 1.2 kilometers and constructing a new bridge adjacent to an existing bridge, spanning an existing freeway. Ongoing design revisions and other technical challenges led the team to rely heavily on 3D modeling and other digital tools to complete the project on time. Combine that with concurrently implementing new design software and a digital project delivery system, and the mission might seem daunting - more than a consulting firm should tackle at once.įor the firm designing the Lathams Road bridge in suburban Melbourne, Australia, the approach turned out to be a successful combination, as new software tools helped the team deal with various project challenges and also prepare for future projects. The design of a new roadway bridge under tight site conditions and a compressed schedule might seem challenging enough on its own. Roe Civil Engineering: Firm designs project under tight constraints while ramping up digital project delivery. Digital Tools Help Australian Team Tackle Challenging Bridge Project 21 Sep, 2022 By: Andrew G.

0 kommentar(er)

0 kommentar(er)